Testing protocol:

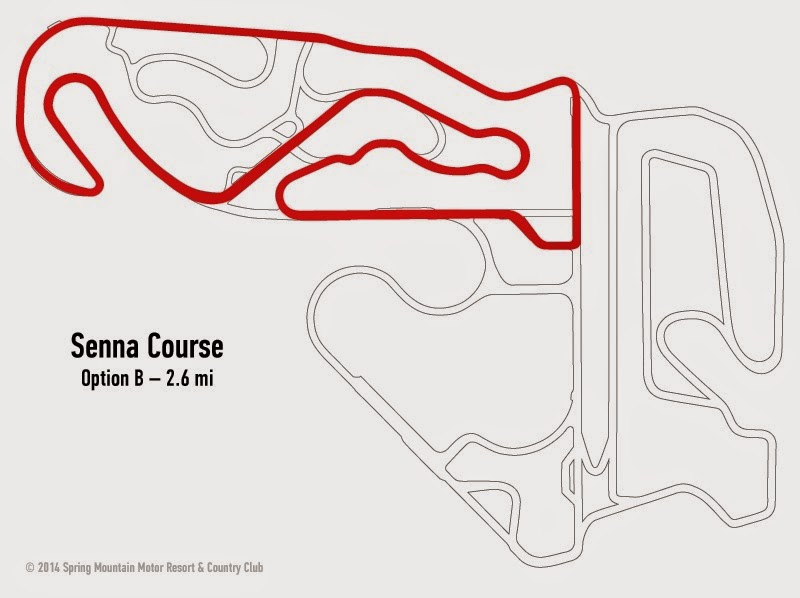

We started with a plan to gradually run the car in and break-in various components. We ran a total of 6 sessions that started with 2 laps and built up to 7 laps. The guys evaluated the car after each session to document. SMMR has dozens of configurations and we ran the Senna course. This 2.6mile track has some high speed sections and also features some elevation change and a high g banked (bowl) turn. This track is mostly smooth but had a few good bumps to test the suspension of the Dragon. We ran the car on the soft setting with the adjustable bell cranks. We had the stock Toyo R888 tires. We ran out of time and did not have the brake bias adjuster installed. We left the rear clam and side pod covers off. Ambient temps ranged from low 80s to low 90s deg F. Set the tire pressures to Palatov recommendations.

We started with a plan to gradually run the car in and break-in various components. We ran a total of 6 sessions that started with 2 laps and built up to 7 laps. The guys evaluated the car after each session to document. SMMR has dozens of configurations and we ran the Senna course. This 2.6mile track has some high speed sections and also features some elevation change and a high g banked (bowl) turn. This track is mostly smooth but had a few good bumps to test the suspension of the Dragon. We ran the car on the soft setting with the adjustable bell cranks. We had the stock Toyo R888 tires. We ran out of time and did not have the brake bias adjuster installed. We left the rear clam and side pod covers off. Ambient temps ranged from low 80s to low 90s deg F. Set the tire pressures to Palatov recommendations.Driving impressions:

The Dragon is a monster. The power is awesome as it accelerates ferociously! The LS3 engine hits rev limiter at 6.5k but the car makes so much torque that I was able to run the track in 3rd and 4th gears. Power application is something you must manage carefully as the torque is really immense. The car accelerates smoothly and I found the pedal progression was good. I could only use wide open throttle a few times per lap as the car is so powerful.

The handling is excellent and was very predictable. The car manages bumps and curbs with excellent composure. Too much gas at the wrong time gets the rear coming out - luckily the handling is excellent and you can catch the car. I had more than one occasion that required some opposite lock to maintain my line. Grip is really high - I can only image how good it will feel with slicks. One of our clients, Bob, was chasing me in his Spec:Race Atom and was impressed with the acceleration and cornering.

Pedal position was good and heel/toe downshifts were no problem. The steering and brakes are unassisted so the feel is excellent. Some muscle is required to drive the car. You get out of the car feeling like you had a workout! The car lacked a dead pedal which is something we should add. The clutch effort on this car was OK on track but too high on the street for regular use. We have a new pressure plate from the 911 Turbo that should reduce effort. The Cosworth dash worked well - the rpms were especially easy to read. Seating position is good, though the seat is too big for me. It should easily accommodate much larger clients than a Lotus!

Technical evaluation:

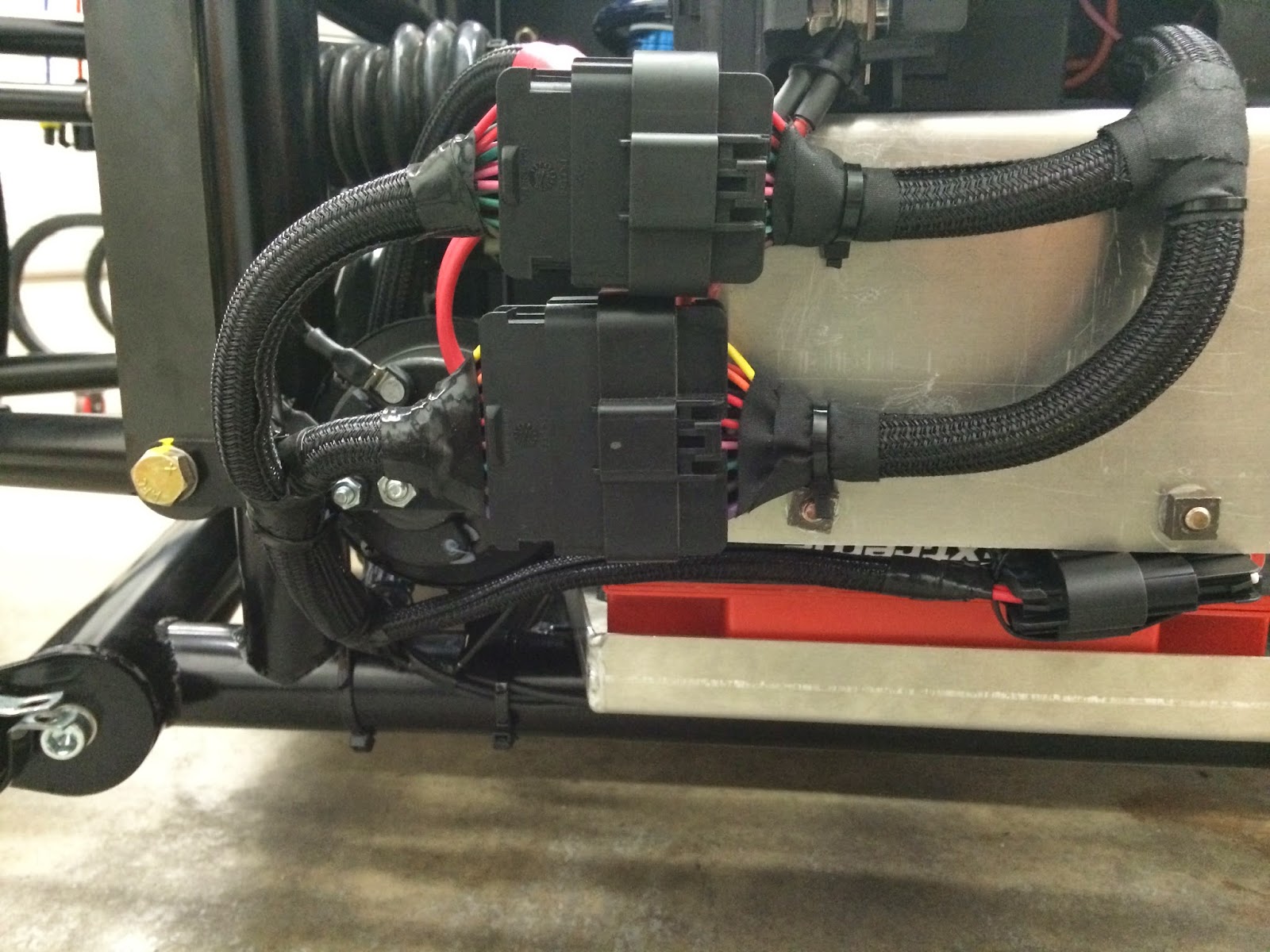

I ran the car with and without passengers and then after each session the guys evaluated the car and recorded any pertinent info. We completed a total of 25 laps and 65 miles of track testing. Water temps and oil pressure were two critical powertrain criteria that we wanted to monitor. We were happy to see that both remain in check during our testing. See below:

- Coolant temps stayed under 210deg F and generally remained under 200 deg F.

- Oil pressure

- at hot idle = 18 psi

- on track = 35-55psi

I had been noticing that the shifting effort was going up on the car as the day progressed and finally Carlos noted it was not shifting after the last session. The guys tore apart the shifter and disconnected the cables and found that the cross gate cable was seized. These cables run within 5" of the ceramic coated cat. The cat gets very hot during use - especially when run on a track at wide open throttle. The cable housing was not shielded from the heat. After returning, we spoke with our cable supplier and have identified a better solution. We will place both cables into a heat shield sleeve to make sure this does not happen again. New high temp cables should be with us by the end of the week.

Overall it was a productive weekend. We will return to SMMR in the next two weeks and test again. We have some more dash and sensor calibration to do before we return. If we can run a solid day without any issues, we will be ready for man Dave T to put the Dragon to a complete test. I suspect he will be able to stay at WOT a bit longer than I...