Track testing with David T.

Carlos and Joe brought the Drakan mule out to the track for some additional testing with our most competent ride and handling engineer. Dave was able to test the new Fox Racing triples that we installed with two different spring rates. Additionally we were able to confirm brake testing and continue to look at other performance and reliability parameters. SMMR remains our test track of choice as their facility is excellent. We ran the 2.1 East track again on this test.

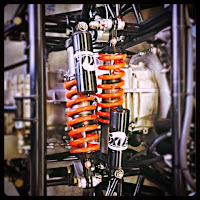

Carlos and Joe brought the Drakan mule out to the track for some additional testing with our most competent ride and handling engineer. Dave was able to test the new Fox Racing triples that we installed with two different spring rates. Additionally we were able to confirm brake testing and continue to look at other performance and reliability parameters. SMMR remains our test track of choice as their facility is excellent. We ran the 2.1 East track again on this test.  The Drakan features Palatov progressive bellcranks (patent pending) that deliver very soft rates at full droop and then get significantly harder as the shocks get compressed. We suspected we could run softer than in our previous tests so brought some soft rates to test. Dave preferred the softer rates and delivered faster laps so they will become our choice as they will also deliver better street performance. We did not get a chance to fine tune the shocks (rebound, hi & lo comp) on this trip. This is on our test plan for the next trip.

The Drakan features Palatov progressive bellcranks (patent pending) that deliver very soft rates at full droop and then get significantly harder as the shocks get compressed. We suspected we could run softer than in our previous tests so brought some soft rates to test. Dave preferred the softer rates and delivered faster laps so they will become our choice as they will also deliver better street performance. We did not get a chance to fine tune the shocks (rebound, hi & lo comp) on this trip. This is on our test plan for the next trip.

One issue that revealed itself was an oil pressure drop under heavy braking combined with a hard left turn. Our oil pressures dropped into the teens. The LS motors have a reputation for this issue and in our previous tests, oil pressure was not a problem. We decided a baffled oil pan insert will be our solution to this issue. One is on its way that we will test later this month. We have a Dailey Engineering dry sump option that will take care of any track addicts who want to run slicks and wings. As is, with Toyo R888s and no wings, 1.2g is attainable. We think the pan insert should be sufficient for those folks who only run occasional track days - unless of course they run at Dave's speeds!

Production Body Fitment: Palatov & Lancair

Our first chassis was tack welded together by Palatov and brought to Lancair for us to start fitting body work. Joe and I made the trip to OR to get this process started. Our Drakan chassis features some differences from the D2 - the biggest being the roll hoops. Our clients wanted roll over protection but were not interested in a full overhead cage. Our hoops can be seen below and are only missing the final tubes that triangulate it to the rear.

The chassis uses chromoloy tubes and now features a height adjustable shoulder harness mounts. Side intrusion changes were made to the chassis as well. New front wishbones with less caster have been built (see right) for reduced steering effort at low speeds. We used this chassis to begin our bodywork fitment. We brainstormed with our partners at Palatov and Lancair to develop our mounting strategy for each panel. The Drakan bodywork attaches much like an Atom with simple external fasteners. Several tabs will be welded onto the chassis so that fasteners can then be used to secure the panels. We wanted to be able to remove the front 'hood'/nose and the engine lid without tools. Both will feature a combination of quarter turns and push release pins.

The chassis uses chromoloy tubes and now features a height adjustable shoulder harness mounts. Side intrusion changes were made to the chassis as well. New front wishbones with less caster have been built (see right) for reduced steering effort at low speeds. We used this chassis to begin our bodywork fitment. We brainstormed with our partners at Palatov and Lancair to develop our mounting strategy for each panel. The Drakan bodywork attaches much like an Atom with simple external fasteners. Several tabs will be welded onto the chassis so that fasteners can then be used to secure the panels. We wanted to be able to remove the front 'hood'/nose and the engine lid without tools. Both will feature a combination of quarter turns and push release pins.

We started with the windshield base. This was our first time to see how the windshield had turned out. A seat was installed in the car and we took turns sitting in the car to check visibility. Though we looked at various perspectives in CAD, nothing replaces sitting in the actual car with actual parts. Our tallest man, Robert (6'4") is shown below in the car. He fits great and looks out from underneath the top of the windshield. Our DOT compliant safety glass windshield is not as tall as a standard windshield - hence the Spyder moniker. This shorter windshield was a concern for us. Robert confirmed that we have a broad range of heights covered. Of course we were also pleased to confirm that his head is well below the roll hoops. We intend to do a windshield-less version as well for the truly hard-core.

We worked closely with our partner, Zukun, to design a body that would be manufacturable and easy to install onto the chassis. Naturally, we discovered that some changes were still needed. The changes have been small but should allow for better manufacturing yields and improved fitment. We are happy with the changes and don't expect it to change the overwhelmingly positive reactions the design has garnered. Palatov will be making carbon fiber fenders for us. We are using the D2 design as it is both cool and functional. One of the first parts can be seen below. More work is needed but they are getting close.

Our first switch panel has arrived and we are pleased with how it has turned out. The panel is back lit so the icons and 'sector111' will be lit up. The ignition switch is a locking type to ensure we don't accidentally shut off the car. The Engine Start button is also lit up and will be easy to see at night. Very high quality switches and wiring all terminating with an automotive grade connector should deliver reliable performance.

We have many more details that we are still working through. New wheels from HRE have been built and I am very excited about them. We have at least 2-3 three more trips up to OR including one that will be our final track test of the first production car. We are shooting to complete this in late April and on track to making it happen.