With high-performance driving, every component of a vehicle plays a crucial role in ensuring optimal performance and safety. One often overlooked but critical element is the wheel bolt stud. These seemingly small components bear the brunt of intense forces and stresses, especially in track-driven cars. In this technical blog article, we delve into changing wheel bolt studs and why it matters for enthusiasts pushing their vehicles to the limit.

Understanding the Basics

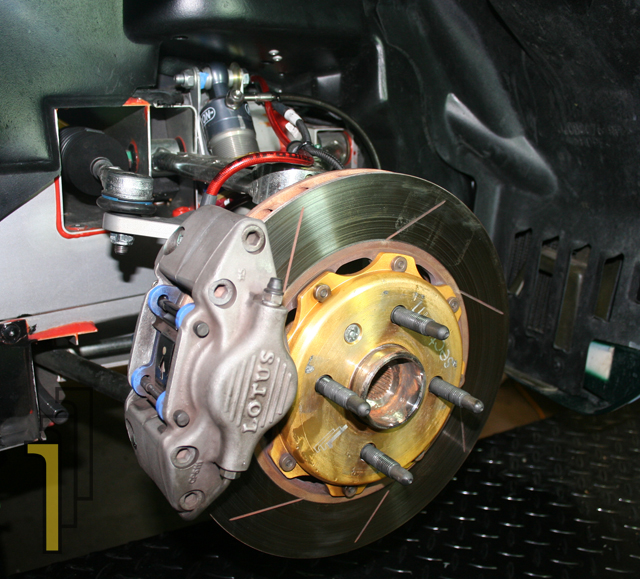

Wheel bolt studs are the unsung heroes that keep your wheels securely fastened to the hub. In a track-driven car, these studs are subjected to extreme loads, including lateral forces during aggressive cornering, intense braking forces, and acceleration stresses. Over time, these repeated dynamic loads can lead to fatigue and, ultimately, failure of the wheel bolt studs.

The Importance of Regular Inspections

Ensuring the safety and reliability of your track-driven car requires a proactive approach to maintenance. Regular inspections of the wheel bolt studs should be a standard part of your routine. Look out for signs of wear, such as elongation of the stud holes, corrosion, or visible stress marks. Detecting these issues early can prevent catastrophic failures on the track, where the consequences are amplified.

Factors Influencing Wheel Bolt Stud Wear

Several factors contribute to the wear and tear of wheel bolt studs in track-driven cars:

Driving Style:

Aggressive driving, particularly frequent hard acceleration, braking, and cornering, puts additional strain on wheel bolt studs.

Track Conditions:

The type of track surface, variations in elevation, and the overall condition of the track can impact the stress on wheel bolt studs.

Wheel and Tire Configurations:

Larger and heavier wheels, as well as wider tires, can increase the load on the wheel bolt studs. Properly torqueing lug nuts and using the correct stud length for your setup are crucial.

Material and Design:

The material composition and design of the wheel bolt studs play a pivotal role in their durability. High-quality materials and designs that distribute stress evenly can enhance the lifespan of these components.

Our HEXstuds and BULLETstuds have been great solutions used on track Elises/Exiges since 2006. We've had great success with them but even they can fail if misused or ignored.

Determining Replacement Frequencies

While there is no one-size-fits-all answer to how often wheel bolt studs should be replaced, several guidelines can help inform your decision:

Manufacturer Recommendations:

Refer to your vehicle and wheel component manufacturers' guidelines for recommended inspection and replacement intervals. Do NOT over torque!

Inspection Results:

If visual inspections reveal signs of wear or stress, it's advisable to replace the wheel bolt studs promptly.

Usage Patterns:

Track enthusiasts who frequently push their cars to the limit may need to replace wheel bolt studs more frequently than casual drivers.

In the pursuit of optimal performance on the track, we sometimes forget about safety. The often-overlooked wheel bolt studs are integral to the safety and reliability of your vehicle. By understanding the factors that contribute to wear and implementing regular inspections, track-driven car enthusiasts can ensure that their wheel bolt studs are up to the challenge. The frequency of replacement may vary, but the commitment to proactive maintenance is non-negotiable for those of us who seek the thrill of high-performance driving without compromising safety.

No comments:

Post a Comment