Brake pad selection is often a tricky affair. A pad that works well for one person may not be good for another. It is good to understand the different types of brake pads along with bedding in procedures. This blog attempts to shed light on these areas to better allow the reader to make the best choice.

There are 2 types of brake pads; those with abrasive friction and those with adherent friction.

- Abrasive friction simply means the brake pad provides friction by touching and rubbing on the rotor itself to create the necessary friction for stopping. Break-in is much easier with this type.

- This type of pad is abrasive, and the rotors will wear much more rapidly - especially when they are cold.

- Adherent friction means that the brake pad is transferring a layer of pad material onto the rotor. As a result, brake performance comes from pad material against pad material. With this type of pad, rotor life is generally much higher. Trail braking can be done very smoothly with this type.

- One negative with these types of pads is that bed-in is more difficult. If you don't do it properly, an uneven transfer layer on the rotor will cause a vibration that appears to be 'warped' rotors. Luckily you can clean the rotors of the uneven pad layer and start once again with proper bed-in. We recommend purchasing pads of this type already 'Pre-bedded'.

Properly bedding your pads and rotors will greatly extend their life and give you maximum performance. Follow the manufacturer's recommendations for best results. I have also detailed our procedure below for adherent friction pads that we sell (G-loc):

Proper bedding instructions for Street Compound (GS-1):

1. Brake from 60mph down to 30mph about 4-6 times.

2. Then let your brakes cool for about 2-3 minutes while driving.

3. Repeat step # 1.

4. Allow the brake pads and discs to cool down to ambient temperature (about 30 minutes or more).

NOTE: Proper bedding of pads & rotors will result in greater performance and longer pad & rotor wear.

Proper bedding instructions for Track or Race Pads (G-loc R8, R10, R12):

1. All new brake pads require a bedding process, start this process by pumping your brakes a few times to assure proper installation. Once on track perform several moderate (medium) near stops (to a very slow rolling speed) to thoroughly warm up the pads and rotors. This should take 1-2 laps. This allows a thin layer of the pad material to be transferred into the micro-grooves of the rotor.

2. After the pads/rotors are warm, perform a series of hard near stops (to a slow rolling speed) until some brake fade is felt. This process should take about 2-4 laps (depending on the track). Once this occurs, then stay off the brakes (as much as possible) and bring your car into the pits/paddock to completely cool. Do not lock the tires during this operation.

3. Allow brake pads and/or rotors to cool down to ambient temperatures; no less than 30 minutes. The total bedding procedure should not take more than 5-6 laps or about 10-15 minutes.

NOTE: The proper way to bed your brake pads and brake discs (rotors) is to bed them on the racetrack, NOT on the street (excluding the GS-1 compound). We know this is not always possible so please find an empty stretch of road.

Warning: Failure to properly bed in your pads could lead to friction material to chunk and break up resulting in poor pad performance and pad life. Improper bedding can also lead to overheating your pads and causing them to glaze over resulting in the car not being able to stop or slow properly.

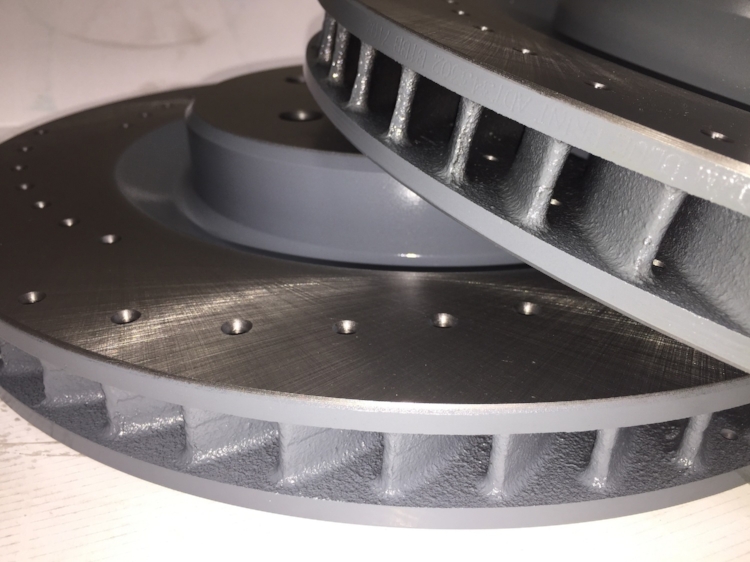

Bedding procedure for brake rotors

New discs (rotors) just like pads need to be bedded in. Proper bedding will increase the rotor life and make it more resistant to thermal cracking. Before installing the new brake discs (rotors), be sure to thoroughly clean discs with clean wipes and brake cleaner. By cleaning the disc surface you want to make sure you have completely removed any and all grease, surface residue, and debris that might contaminate or damage the brake pads. Once the discs (rotors) are installed on the vehicle perform the following procedure. Please note that you can bed new pads & discs (rotors) at the same time.

1. Start out with several near stops for the first 1-2 laps, while gradually increasing your speed and brake force with every stop.

2. Next, do another 1-2 laps at normal speed followed by a cool-down lap. The gray coloration is the pad material depositing a transfer layer of material into the micro-grooves of the disc. This process is pinnacle in achieving the best performance and life out of the rotor.

3. Then allow rotor(s) to completely cool down to ambient temperature.

Proper USED brake rotor bed-in procedures:

1. If rotors have been previously bedded with G-loc or Carbotech brake pads, then bedding the rotors again is not necessary.

2. If rotors were previously bedded using a different manufacturer’s brake pads; then it is strongly recommended that the used discs (rotors) be reconditioned/turned and meet minimum specification requirements.

3. Start out with several near stops for the first 1-2 laps, while gradually increasing your speed and brake force with every stop.

4. Next, do another 1-2 laps at normal speed followed by a cool-down lap. The gray coloration is the pad material depositing a transfer layer of material into the micro-grooves of the rotor. This process is pinnacle in achieving the best performance and life out of the rotor.

5. Then allow rotor(s) to completely cool down to ambient temperature.

NOTE: Brake pads should be checked regularly. If pads are wearing evenly, then the pads can be used almost down to the backing plate.

NOTE: Do not drag your brakes; meaning, do not continually drive around the track with applied pressure to your brake pedal. This does not bed brake pads and/or rotors properly. This can severely hurt the performance and life of your brake pads & rotors.

2 comments:

Choosing the right brake pad is important since performance and rotor life depend on the type you select, whether abrasive or adherent friction. For professional help and safe installation, you can check brake repair for expert service.

Brake pad selection can be tricky because what works for one driver may not suit another. There are two main types of brake pads: abrasive friction and adherent friction.

Abrasive friction pads generate stopping power by rubbing directly on the rotor, making break-in easier, but causing faster rotor wear, especially when cold. Adherent friction pads transfer a layer of pad material onto the rotor, which provides smoother braking, longer rotor life, and better trail braking. The downside is that proper bed-in is more critical; uneven pad material can cause vibrations that mimic warped rotors. Pre-bedded pads are a good option to avoid this issue.

For reliable parts and options, check Used Cars Orlando.

Post a Comment